EVEREST INTERNATIONAL CONSULTING (LLC)

- Welcome

- How We Meet Your Needs

- Our Consulting Services

- Industries Served

- Our Technical Expertise

- What We Specialize In

- Expert Help in Patent & Intellectual Property Issues

- Expertise in Polymer Modification (incl. Grafting)

- Expertise in Thermoplastic Elastomers

- Expertise in Wire & Cable Compounds

- Expert Help in "Green" / "Sustainability"

- Previous Consulting Experience

- Background of Dr. Adur

- His Patents, Papers & Presentations

- Recommendations

- Contact Us

- Useful Links

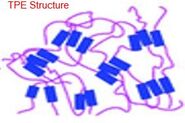

What are Thermoplastic Elastomers (TPEs)?

|

Expertise in Thermoplastic Elastomers:

Over 10 of my more than 70 patents dealt with Thermoplastic Elastomers (TPEs).

During my time as Development Manager at BP Chemicals, I developed formulations on TPOs and partially crosslinked TPOs and TPVs and PVC-based and non-PVC-based Thermoplastic Elastomers compounds for automotive, military and personal care applications and use and wire and cable applications including those for zero halogen and zero smoke applications. I also developed specialty TPEs with properties like adhesion, paintability, drapable, oil resistance, and many other higher margin but smaller volume specialty applications. I also improved quality and doubled plant production rate of thermoplastic olefinic elastomer product line dramatically in 6 months.

During my time as Technical Leader at PolyOne, I developed proprietary TPOs and TPVs based on PP-EPR, PP-EPDM, HDPE-Plastomer, PP-NBR, NBR-PVC, PVC-NBR, PP-SBR, HDPE-SBR, PP-SEBS, HDPE-SEBS, HDPE-Plastomer, Nylon-Polybutene and also for wire and cable customer companies to get into new markets including automotive, energy, industrial and automotive gaskets. Some were for specialty applications like low friction TPEs.

I developed courses in Material Selection & Substitution, Polymer Compounding, and Adhesion of Polymers for Univ. of N. Carolina at Charlotte (all in 1993). Taught online courses on Compatibilization of Polymer Alloys, Blends and Composites; Reactive Compounding of TPEs and TPVs; Optimization of Polyolefin-Based Alloys and Composites (Advanced Formulations Course); Reactive Compounding of TPEs and TPVs;

As an independent consultant, I have served as Expert Witness in product liability lawsuits, one in automotive TPOs (which went to trial and our side won), two in polyolefin and ABS injection molded parts (one was settled out of court while the other was dismissed based on my finding) as well as in four patent disputes.

I also developed cardiology catheter and an elastomer tubing for single pump housing for medical device companies with new annual sales of $300 million.

I developed numerous thermoplastic elastomer products and engineering plastics compounds for various companies.

I also characterized cryo-ground recycled tire rubber & developed TPE compounds based on this ultra-fine ground powder.

Performance Requirements:

|

End Use Applications:

|