EVEREST INTERNATIONAL CONSULTING (LLC)

- Welcome

- How We Meet Your Needs

- Our Consulting Services

- Industries Served

- Our Technical Expertise

- What We Specialize In

- Expert Help in Patent & Intellectual Property Issues

- Expertise in Polymer Modification (incl. Grafting)

- Expertise in Thermoplastic Elastomers

- Expertise in Wire & Cable Compounds

- Expert Help in "Green" / "Sustainability"

- Previous Consulting Experience

- Background of Dr. Adur

- His Patents, Papers & Presentations

- Recommendations

- Contact Us

- Useful Links

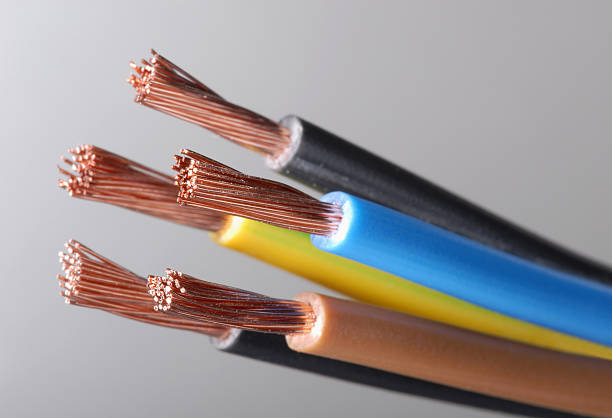

Background in Wire and Cable Compounds:

Compounds based on:

Performance Requirements:

|

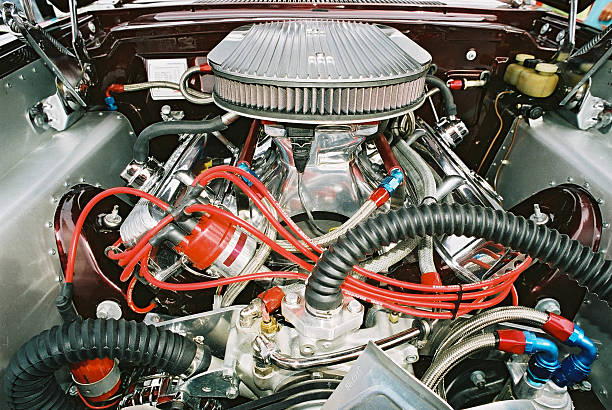

End Use Applications:

|